IMEG partnered with a Tier I automotive manufacturer to increase productivity on a high-volume assembly line at their 120,000-square-foot production facility.

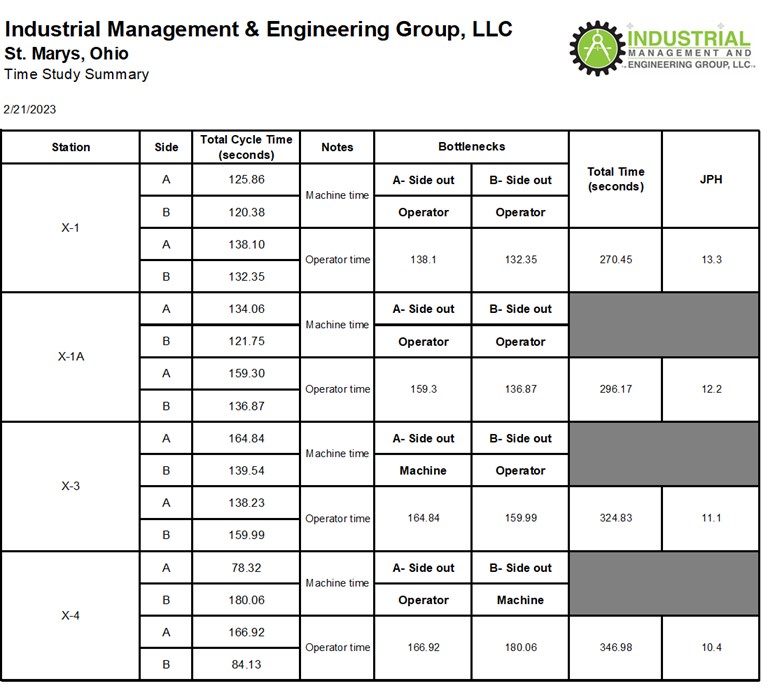

The manufacturer was facing serious bottlenecks and inefficiencies on the assembly line, which were preventing them from meeting production targets:

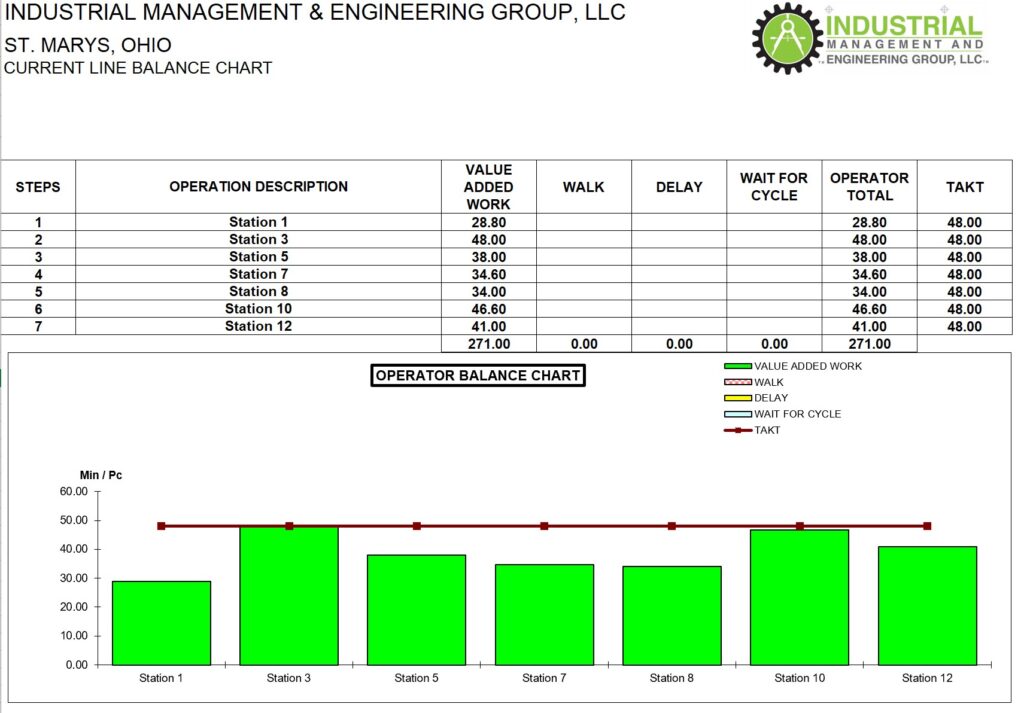

To address these productivity and ergonomic issues, IMEG implemented a structured assembly line improvement strategy including: