IMEG specializes in optimizing material flow within manufacturing environments to improve efficiency, reduce waste, and streamline operations. Our material flow analysis services focus on mapping, managing, and continuously improving how materials and operators move through your facility.

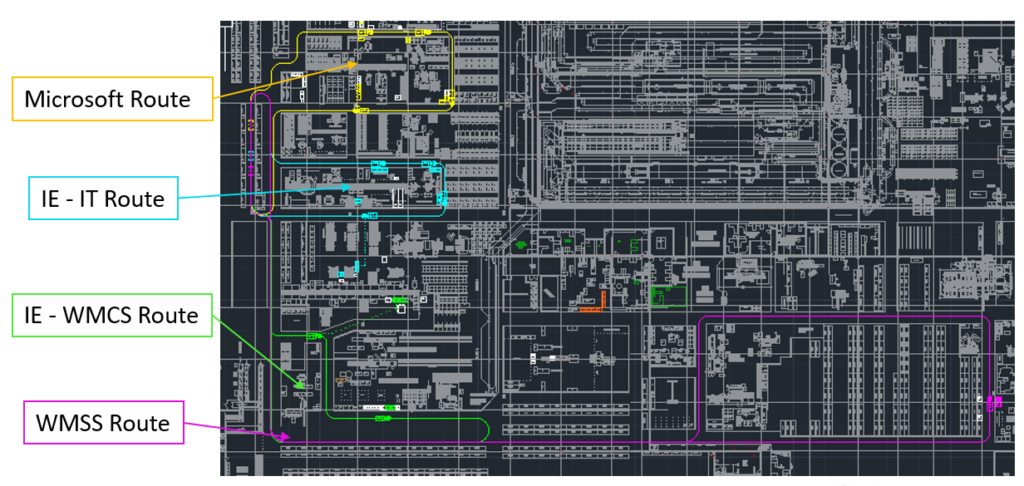

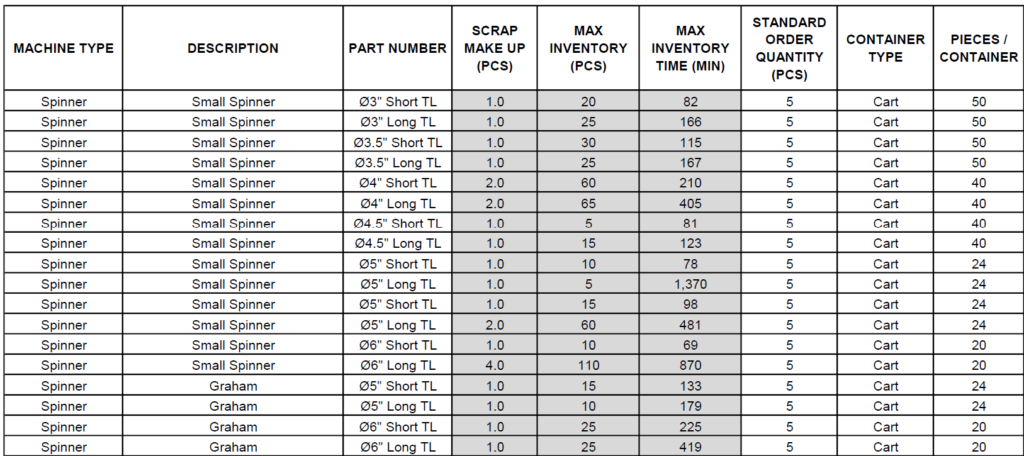

travel distance analysis

material replenishment planning