At IMEG, we specialize in capacity planning for manufacturing operations, helping you accurately measure, analyze, and plan for current and future production needs. Out structured approach ensures that your machines, labor, and shifts are fully optimized to meet demand and support growth.

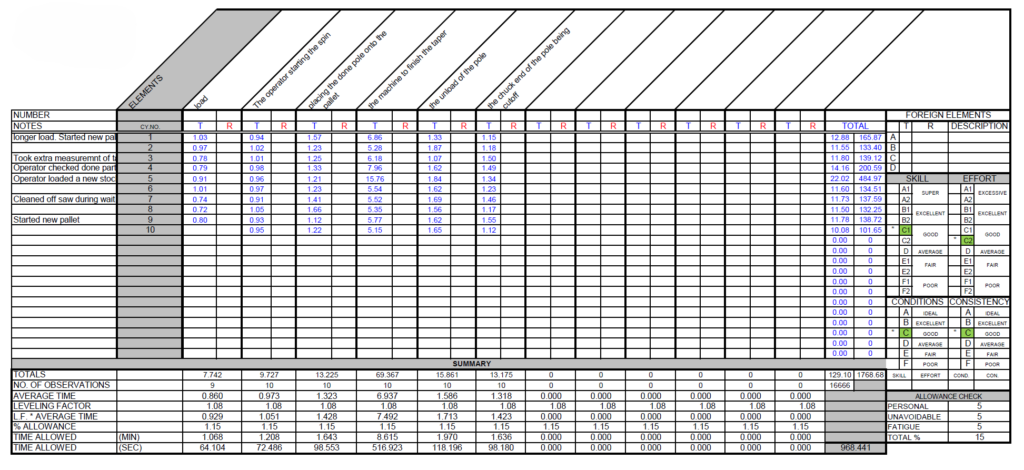

production planning

capacity planning

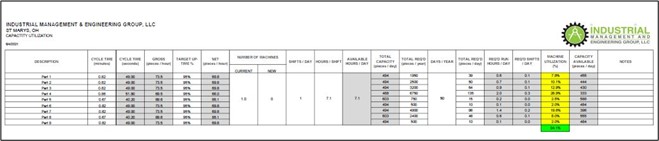

machine utilization analysis