In today’s competitive manufacturing and production environment, manufacturing facility layouts are an integral part of business planning. Poor facility layouts can result in excessive material handling, inefficient workflows, and wasted space while having the optimal layout boosts business productivity.

That is why facility layout planning has become essential — and AutoCAD offers a powerful platform to optimize your layout with precision. Whether designing a new facility or reconfiguring an existing one, using AutoCAD allows you to visualize spatial relationships, eliminate inefficiencies, and analyze multiple scenarios before committing to physical changes.

In manufacturing and industrial environments, facility layout planning is a strategic activity that directly impacts efficiency, safety, and cost-effectiveness. At IMEG, we leverage AutoCAD, a powerful drafting and design tool, to develop, refine, and optimize plant layouts with precision and confidence.

AutoCAD allows engineers and planners to create highly detailed, scalable 2D models that accurately represent all components of a facility. Its key capabilities include:

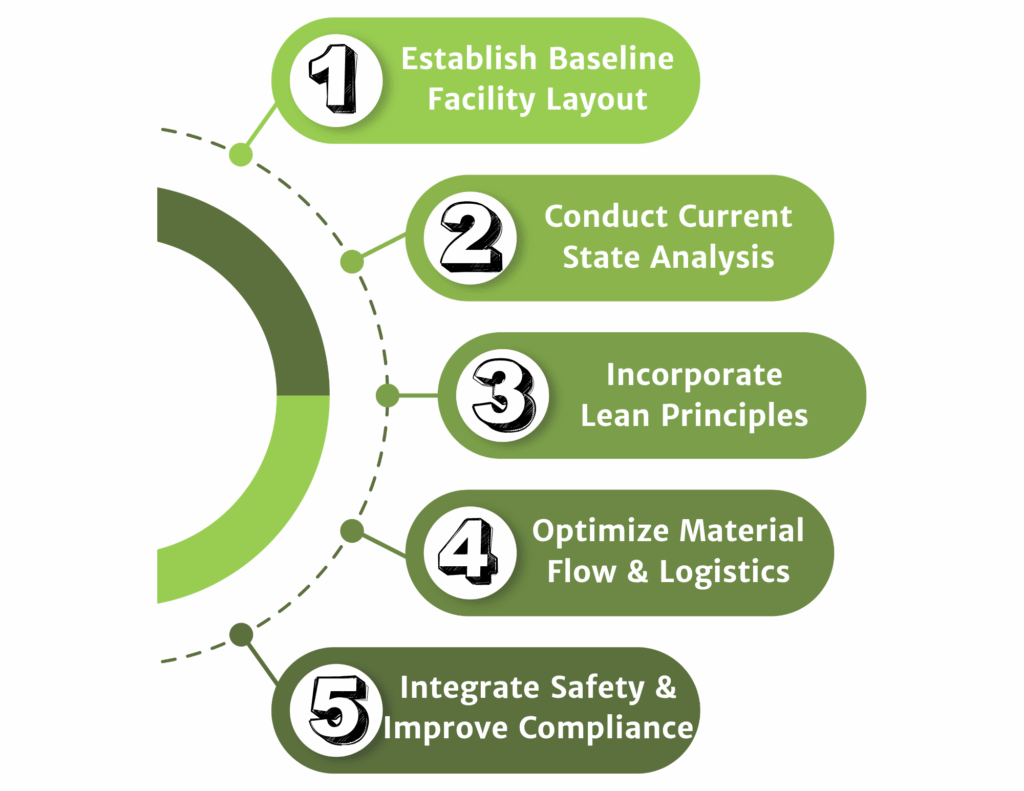

Below are five practical ways IMEG uses AutoCAD to support and enhance facility layout planning:

The first step in any layout improvement is creating a detailed and accurate baseline. IMEG achieves this through field measurement, starting with structural components and followed by machines, equipment, and storage systems. Using appropriate datums, we map:

This current state AutoCAD layout becomes the foundation for further analysis and ensures every decision is rooted in real-world accuracy.

With a reliable baseline in place, IMEG conducts a full operational analysis to uncover inefficiencies. Using AutoCAD, we perform:

These analyses, powered by accurate AutoCAD layouts, give us confidence in our findings and help communicate opportunities for improvement clearly and visually.

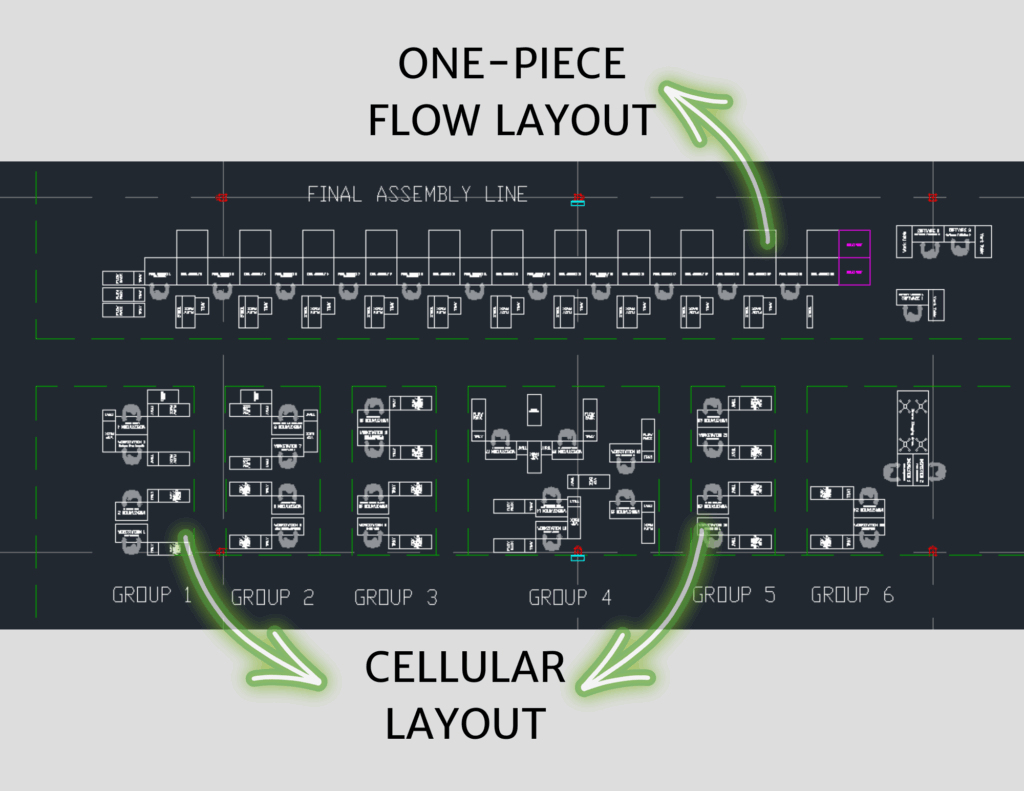

To eliminate inefficiencies, IMEG incorporates lean manufacturing principles directly into each facility layout. This includes:

This lean-driven approach improves workflow, reduces movement, and supports continuous improvement.

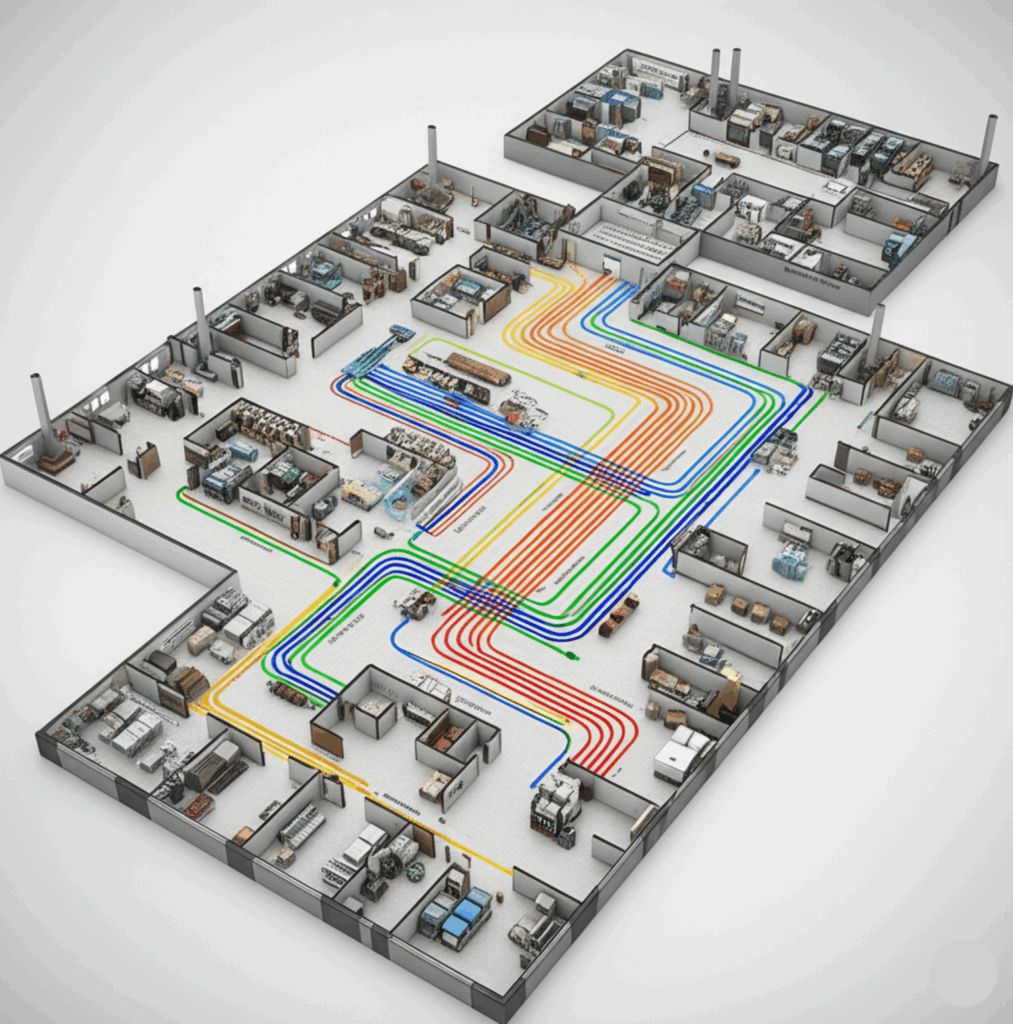

Material handling and flow are critical to plant performance. IMEG supports logistics optimization initiatives such as:

In AutoCAD, we detail layouts with station and rack numbers, apply color-coded polylines to indicate flow direction, and mark congestion points. This visual representation enables smoother implementation of logistics strategies and better cross-team alignment.

Safety is integral to every layout decision. AutoCAD helps IMEG ensure that all relevant OSHA and NFPA standards are met. Our dedicated safety layers may include:

By embedding these features into the AutoCAD layout, we support a safer working environment and make compliance easier to manage and verify.

AutoCAD is more than just a drafting tool — it’s a core component of IMEG’s facility planning and continuous improvement process. From baseline measurement to lean implementation and logistics optimization, we use AutoCAD to deliver layouts that drive operational excellence.

If you're planning to reconfigure your facility or just want to get more out of your existing space, contact us. Our layout planning approach, powered by AutoCAD, combines field expertise with digital precision to help you improve flow, reduce waste, and boost plant performance.

Contact Us