Streamline operations, reduce waste, and improve productivity with Lean Manufacturing consulting. We help manufacturers implement proven lean tools like 6S, Kaizen, and Value Stream Mapping to unlock operational excellence.

continuous improvement

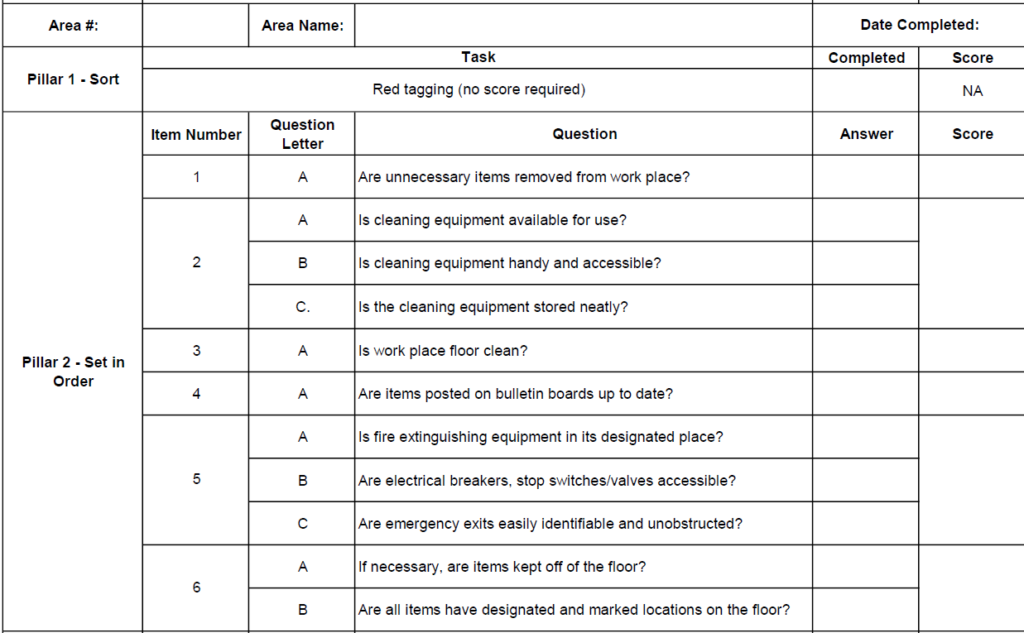

lean, 6s

kaizen events

lean manufacturing

industrial lean consulting